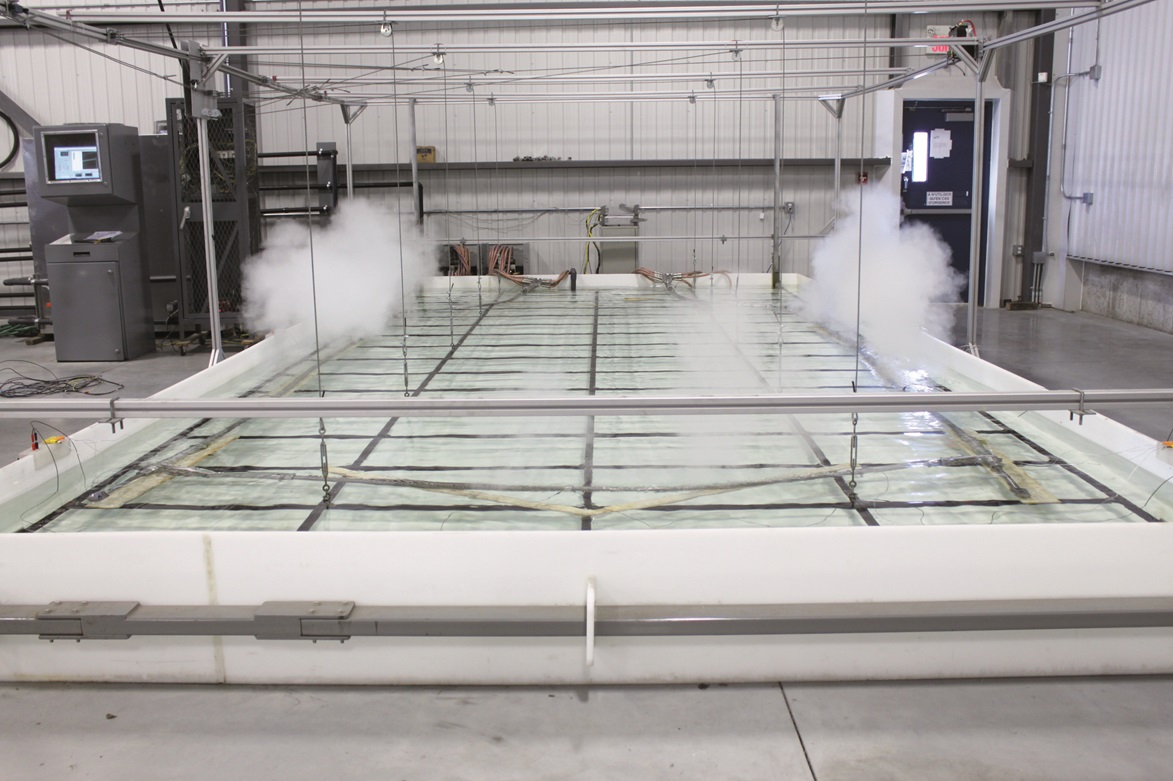

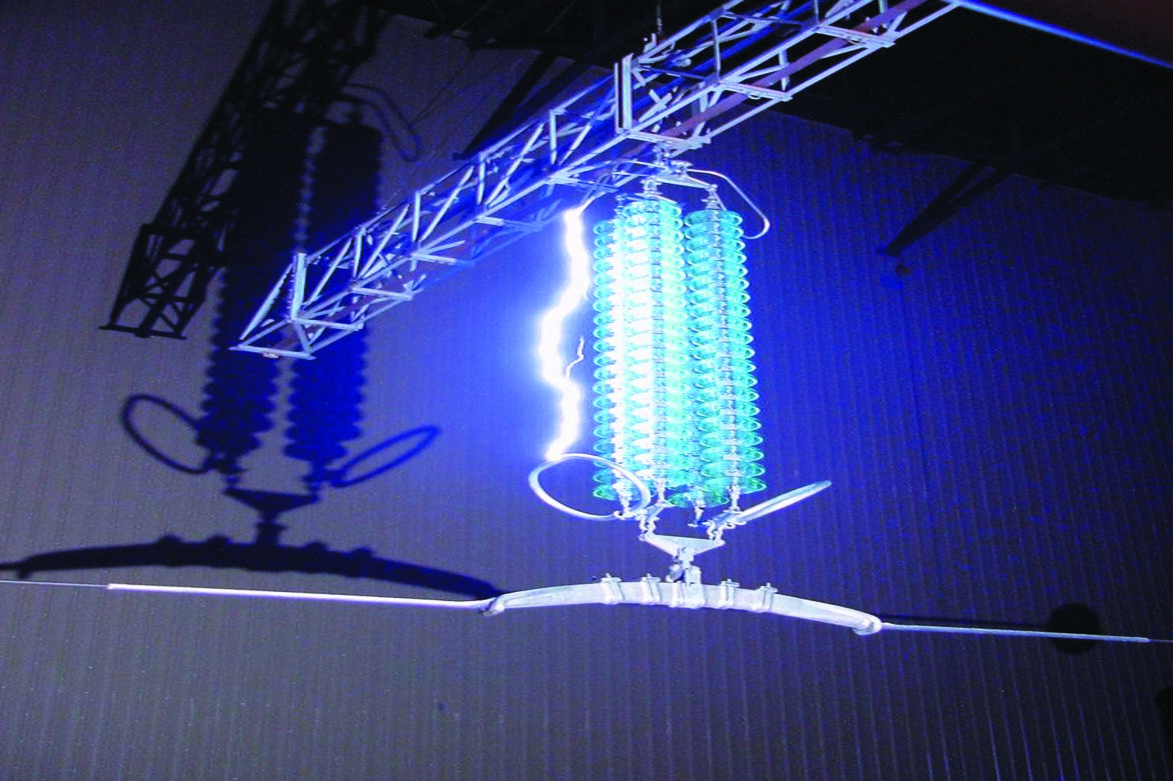

Laboratories and testing

The laboratory is vital in assisting both design activities and product verification during the design stage. It supports the technical department in its activity of research and development while in the product verification stage all quality control mechanical verifications and tests are carried out to include batch acceptance tests.

A testing laboratory able to characterize and qualify HMS conductors and accessories

Our transmission has state of the art resources among the best in the world which means that low sag/high ampacity conductors and accessories can be fine-tuned and qualified. The studies and trials are performed inaccordance to the power, environmental, and configuration parameters of the line to be fitted. All tests comply with the requirements of the international reference standards or/and with the technical specifications of each country.

We can perform also independent tests under accreditation or not for third party (cable manufacturers, utilities..)test bench systems have flexibility to meet specific requirements.